Wedge® Mixer

Perfect HACCP solution for the traditionally-hazardous area between shaft and tank seal.

The most troublesome and frequently-happening contamination at the sealed area between shaft and drum can be prevented by the patented seal system.

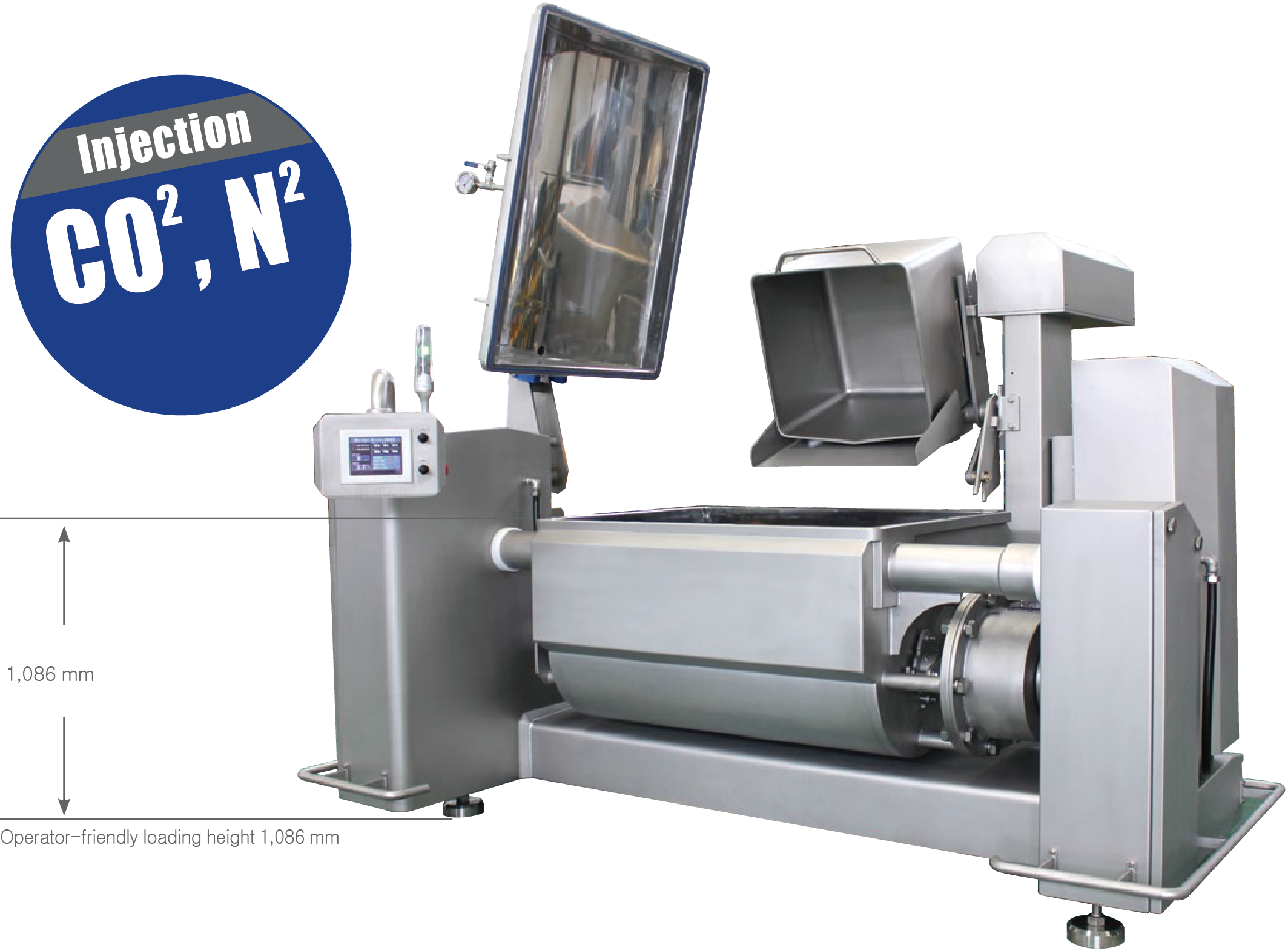

Smart Appearance, Fully Open Access

With a good deal of durability, its gorgeously looking simple gear drive offers a fully open access to operators, making it easy to monitor and do maintenance jobs over the critical area.

Internationally-patented shaft-seal system

In conventional mixers, meat could enter shaft bearing and could reversely return into drum, which hygienic experts take as a hazardous risk. The patented seal system makes the reverse traveling of meat mechanically impossible. Meat would only have one-direction flow (in to out). The shaft-seal is easy to dismantle and clean for daily-base maintenance jobs.

What features Wedge?

- Patented Wedge Mechanism

- Easy Dismantling Shaft Seal System

- Comfortable Loading Height 1,086 mm

- Round frame leading to no water-residue

- Controls and Gearbox located separately

- Built-in Hydraulic System, Better Space Efficiency

- Completely Sealed Stainless Steel Frame

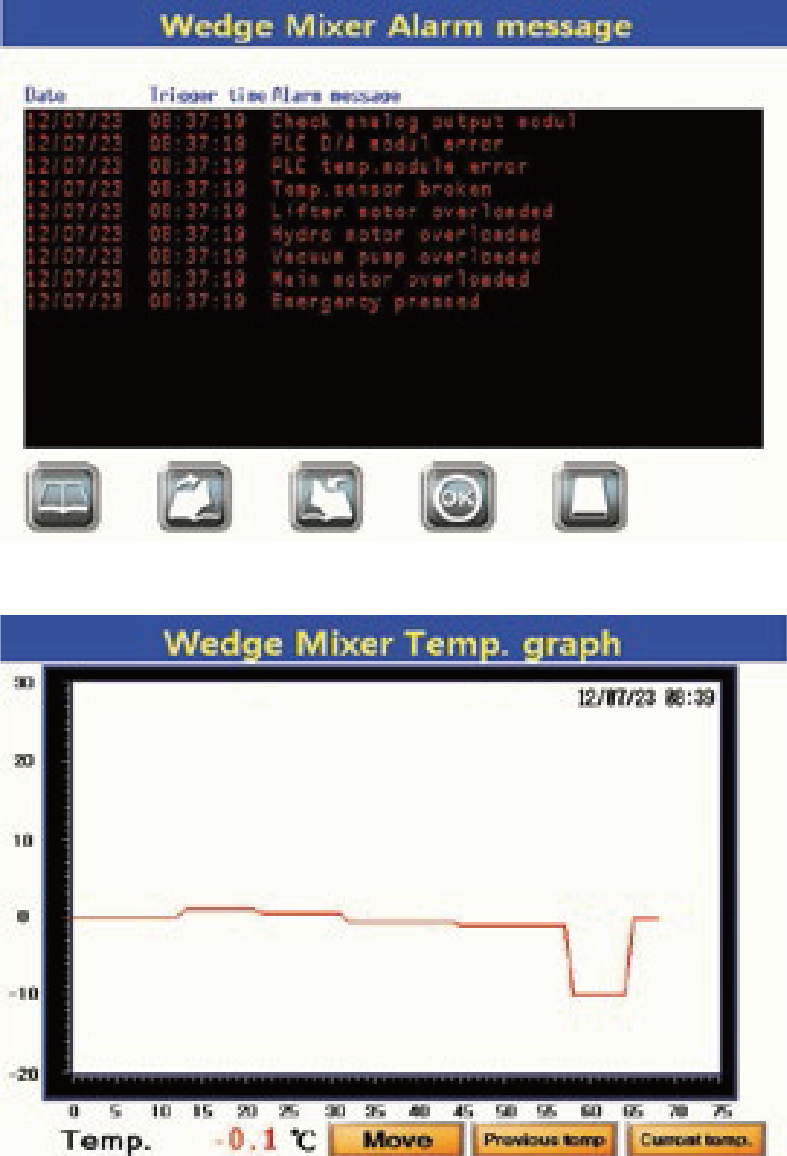

- Easy Programming, Easy Recalling

- Forward/Reverse Rotation, Variable Mixing Speeds, Resting Time, Cooling Operation.

- 12.1 inch Full Color Wide Touch Panel in Swing-Arm

- Manual Button Controls - Built-in Temperature Sensor (On Request)

- Vertical Dumper instead of Conventional Over-Turn Device.

- Quick Handlers in the Swing-Arm.