HI-COOK

Vacuum packed products are not as germless as it would often be thought. In fact, they are so vulnerable to germs and microorganism picked up during vacuum packing process. It is very much necessary to get rid of these germ and microorganism in a shortest possible time, otherwise product quality would degrade very quickly.

HI-COOK Pasteurizer efficiently kills the germs and microorganisms which are mostly staying on the product surfaces.

HI-COOK pasteurizer works in PID temperature control and its unique first-in/first-out mechanism, ensuring stabilized and equalized process results.

HI-COOK pasteurizer is working with the sophisticated electronic valve for steam supply(for pasteurization) and the high efficiency indirect heat exchanger(for cooling). The standard temperature of water in pasteurization process is 82 to 85 deg. C, and the temperature difference during the process is within +/- 0.5 deg. C.

It is technically impossible to evade germ-contamination during the vacuum packing process unless your jobs are done in a completely pure aseptic room. One way or the other, germs contact products and get packed together.

Now the remaining question is how we can efficiently get rid of those germs which are inside vacuum packages. Pasteurizer is the answer.

- Precise temperature control (PID)

- First in, First out

- Soft transportation evading pin-holes

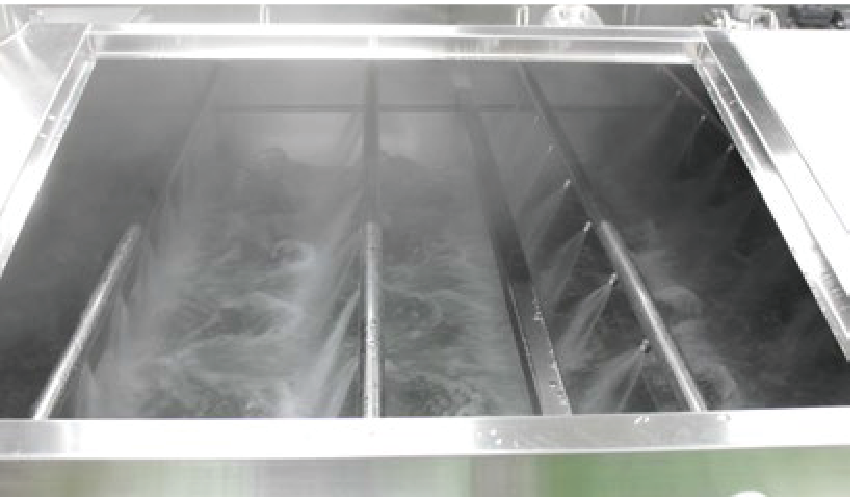

- V Jet nozzles - Simple cleaning hatches

- Digital process time controller

- PC monitoring (LAN to be supplied by user)

Every corner and component of pasteurizer is the outcome of such many installations and experiences for the last 30 years, such as inclining angles of transport conveyor, injection angles of V-jet nozzles, easy-access gear box, etc.

V-jet nozzles are keeping the products under water, which would otherwise float over water. Floating itself cannot be avoided, but with the Vjet nozzles, the products can continue traveling to the outlet under the full process effect. Products are neither stopping nor retreating in their traveling, which is its proud advantage in the market. Products are getting in and out in order